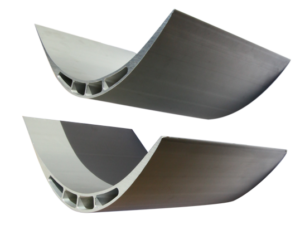

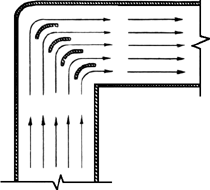

HVAC turning vanes are curved sheet metal fins placed in air-conditioning duct work at a point where the duct changes direction, typically a 90 degree turn. They are used to promote a more uniform airflow and reduce pressure drop.

When airflow changes direction in a duct that lacks turning vanes, the walls of the duct must absorb the sudden impact of the air and redirect it to the correct direction. The primary purpose of turning vanes is to create a smoother change in direction for the airflow. The resulting reduction in pressure loss is a more efficient system. While the turning vane surfaces do add a small amount of friction, the amount of energy lost to friction from the vanes is negligible compared to the gains realized from minimizing the abrupt change in direction.Designers should always specify the highest efficiency fittings possible within the owner’s budget, to increase system efficiency at every available opportunity. HVAC contractors should not take it upon themselves to add to or remove turning vanes from an engineer’s designs. Each system is designed to a specific total static pressure, and removing or adding turning vanes where they have not been accounted for in the engineer’s calculations will make the system function differently than intended. In a worst case scenario, the changes to the system may cause it to become incapable of supplying the required airflows to all zones.