Note before reading: This is part one of a new blog series in which Mestek Machinery explores the procedures and practices in the fabrication of ducts and duct connectors.

Many different concepts are used in the fabrication of ductwork for ventilation, air conditioning, and heating systems. Practices vary throughout the world. The important factors to be considered in manufacturing ducts are:

- Satisfactory air-tightness of completed duct

- Vibration-free operation

- Even flow of air without undue pressure loss in system

- Structural soundness to serve the purpose of conducting heated or cooled air within the system, with a minimum of turbulence, and at levels where comfort will not be reduced within the areas to be ventilated

We will attempt to point out here the various methods of manufacturing ductwork which are commercially feasible.

Three Ways of Making Ductwork

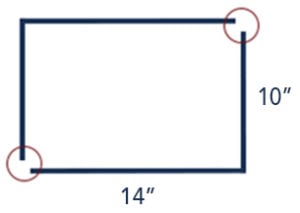

Two-Piece (Figure 1)

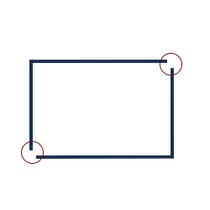

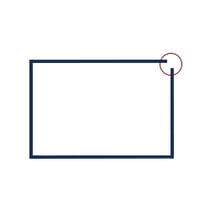

One-Piece Wrapper (Figure 2)

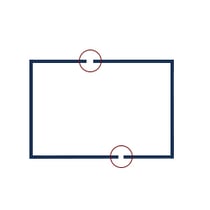

Large Pieced Section (Figure 3)

There are three basic ways of making duct, based on the position of the joint or fastening lock. These are:

- The two-piece duct with two comer locks diagonally opposite one another (Fig. 1)

- The one-piece wrapper with a single corner lock (Fig. 2)

- The two-piece center lock method-large pieced sectionwhere two locks are placed at the centers of opposite flat sides (Fig. 3)

Four Methods of Making Corner Joints and Seams

Although there are other methods used, the most common methods of forming corner joints (locks) and seams are:

- Pittsburgh lock and right angle

- Button Punch Snap Lock

- Double Seam

- Standing Seam and right angle

Before discussing these methods, let us first examine the means of calculating the duct material and the basic notching operation.

Calculating the Material

Select proper type, grade, and thickness of material, according to the job that it is designed to handle. The sheet is measured to give the proper width of completed duct – with proper allowance of metal for corner joint. Excess material is either trimmed with a shear or slitter.

The completed duct shown-measuring 10″ x 14″-could be made with either one corner joint at “A” or two corner joints-“A” and “B”. Allowance of metal for each joint would be 1¼” (r for Pittsburgh lock and C for right angle bend). Thus, the material needed would be:

Two-piece: 2 x (10″+14″+1¾”) =

50½ Total Material

One-piece: 2 x (10• +14″) +1¾” =

49¾” Total Material

The difference between the two figures is the amount of material required for the one extra joint.