This is the second installation of a blog series in which Mestek Machinery explores the procedures and practices in the fabrication of ducts and duct connectors. You can find part one here.

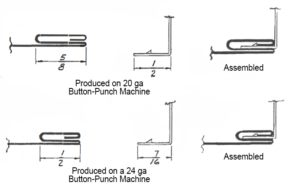

How to Make the Button Punch Snap Lock

The Button Punch Snap Lock is used in the same way as the Pittsburgh lock for joining comer sections of sheet metal. Its big advantage is that no additional “hammer-over” operation is required-with a direct result of less labor cost in assembly. It is easier to assemble-duct can be taken to job site nested in component form, with a saving in space-and assembled easily on the Job site. It also is much quieter in assembly, since no mechanical or air tools are required for hammering over.

This lock has been tested for strength and leakage and found to be comparable in all respects to Pittsburgh lock. This work was performed by the Pittsburgh Testing Laboratories, an independent research laboratory. The results were published in the SMACNA (Sheet Metal and Air Conditioning Contractors National Associatjon, Elgin, Illinois) Duct Manual, and SMACNA has approved its use as an alternate method.

Button-Punch Snap Lock Flanger

This is a companion tool to be used with the 20 or 24 gauge Button Punch Machines, or the Button Punch Rolls, as an auxiliary operation with the Cleatformer. It produces the curved sections (one directional), outside or inside radius, in a two-step operation on the same machine. This allows the contractor to install a complete Button-Punch job for straight as well as curved fittings. The range of machine is 20 to 28 ga. galvanized.

See the Mestek Machinery Catalog for further details.

How to Make the Double Seam Lock

The Double Seam is also called “Acme lock,” “hammer lock” and “pipe lock” in the sheet metal trade. It is normally used in the fabrication and joining of the round pipe or in joining or piecing together two sheets of metal to form a large wrap-around section for square or rectangular ductwork. The double seam can be run as an auxiliary operation on the Pittsburgh type machines, Cleatformer, or auxiliary of Button Punch Snap Lock Machines. The great advantage of producing on a Lockformer Machine is the faster method of forming and, most important, the consistency of resultswhich makes joining together easier and faster.

Double Seam locks can be produced in 16 through 30 gauge material, depending on the type of rolls and machine to be used.

Type L-16 through 22 gauge

Type S-22 through 28 gauge

The above are all available on Model 16 or 18 gauge Lockformer, Cleatformer or Button Punch Snap Lock Machines as auxiliary operations. Standard Double Seam (20-26 ga.) can be produced on 20 or 22 ga. Lockformer.

How to Make the Standing Seam Lock and Right Angle Flange

This profile is used for stiffening, or for joining sections together in roofing or in ductwork connections; also used for boiler lagging where insulation is required around the casing of a boiler jacket. Standard rolls are available for a ¾” high standing seam and a companion right angle flange by using entrance gauge filler-block. The section is then secured by means of a hand punch, screw or rivet (16 gauge capacity). Also available in 1¾ “-high section for 16 gauge capacity, with companion right angle flange for Standing “S” Cleat Machine.