There are a lot of complex ways we can maximize our shop’s efficiency, but sometimes the simplest solutions, like keeping an organized workspace, are the best solutions.

Moving from job to job means resetting your press brake and swapping out tooling. If your equipment isn’t stored and labeled appropriately, you could be setting yourself up for production delays. Since time is money, your workshop should be as organized as possible to minimize those delays. So where can you start?

1. Reduce the clutter

You shouldn’t have “piles” of anything in your shop, least of all tooling equipment. There needs to be a designated area for your tooling where they can be laid out separately. This is especially important if you have a few different operators assigned to work on particular bend operations. If another operator is shifting around someone’s tooling while searching for their own, there are going to be delays with every project transition.

2. Label, label, label

A standardized labeling process should be established for all tooling, regardless of the operator staff’s seniority. New hires will find labeling particularly helpful, but if the tooling label clearly indicates shape, measurements, gauge restrictions, and other vital info, swapping it out becomes a simple act of grabbing the right one. Color coding the tooling by project use can cut down search time, as well.

3. Assigned tools

If multiple machines are sharing die or punch parts, you’re bound to run into a situation where one operator may have to wait while another is using the part he needs. The flow of production is important, and even if the waiting operator is pulled onto a different project to better use time, it doesn’t necessarily maximize efficiency. Consider dedicating certain parts to certain machines, and doubling up on parts that see particularly high use.

4. Leave it to the machine

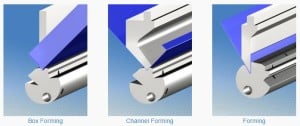

The organization solution that requires the least change in process is finding a bender that has built-in and easily changed tooling. Roto-Die hydraulic benders require a simple lever adjustment to change tooling on the fly. No need to search for a part, or find its proper place when returning it. Adding a Roto-Die machine to your current machine lineup also would solve the problem posed by sharing tooling between machines, as Roto-Die tooling is only used by that machine (it is built in, after all).

Take these tips, neaten up your workspace, and boost your metal fabrication shop’s efficiency. Got a process that works great for your operation? We’d love to hear it! Comment below to share some tips of your own.