This is the second installation of a blog series in which Mestek Machinery explores the procedures and practices in the fabrication of ducts and duct connectors. You can find part one here , part two here, and part three here.

How to Make Spiral Duct

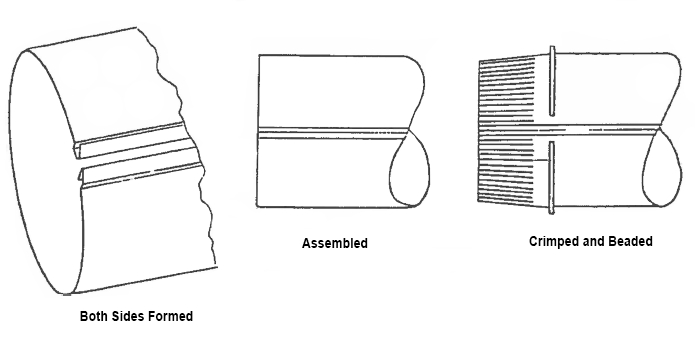

There are many methods of making spiral duct (or pipe), from 3″ minimum diameter to greater diameters. The method to be used varies with the requirements for the duct’s usage. In all cases, it is necessary to form the two sides of the locks first, roll into proper diameter and bead and crimp the end. The crimp reduces the diameter so that the pipe can be assembled into the next length. The bead serves as a positive stop for the second length of pipe. It is, then, normal procedure to secure the lengths with sheet metal screws and tape the joint with duct tape to seal off any air leakage.

There are several common methods of forming the lock:

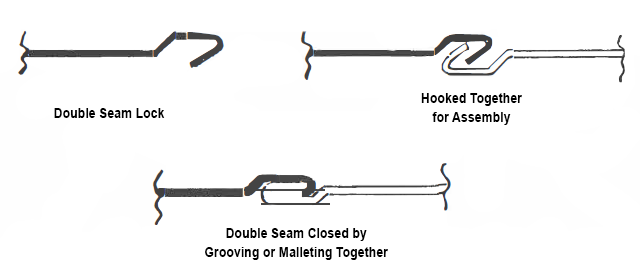

The Double Seam is probably the most common method used in sheet metal shapes since it can be used for light and heavy gauge materials-30 gauge through 16 gauge. In all cases, the Double Seam is formed and completely assembled in the shape before it is taken to the job for installation. The duct is cut there to correct length with hand snips.

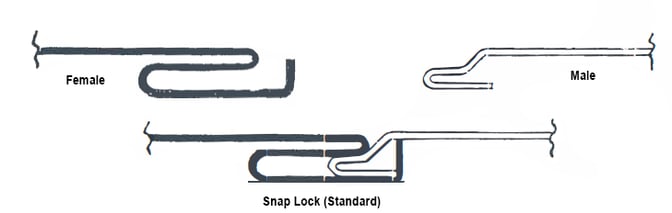

Standard Snap Lock is a type of lock used by sheet metal contractors, as well as production shops who make duct for resale. Its main advantage is m permitting convenient shipment of large quantities of nested lengths, to “snap-assemble” on the job, as needed. This reduces the amount of shipping and storage space wasted when duct is shipped after shop assembly. Control of the length of male 180° bend will give either a tight or loose snap to the pipe.

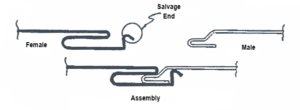

The Reeves Snap Lock is another form of lock similar in application to the Standard Snap Lock above, but with a distinct advantage in its manufacture, having a salvage edge on the female side that increases raw edge strength, reduces the possibility of pipe damage in transit. This also allows for a greater shearing or slitting error tolerance in blank size. Excess material is taken care of in the female salvage edge.

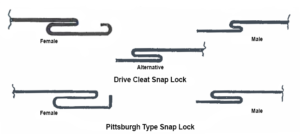

Variations of Round Pipe Locks

All of the above shapes perform the same basic function as the Standard Snap Lock or Reeves Snap Lock but are used for competitive reasons in the sale of this product to the trade.

Modern Means of Producing Spiral Duct

Here at Mestek Machinery, we produce a number of under our ISM Machinery brand. ISM Machinery is a spiral fitting machine manufacturer, specializing in the service and sales of spiral tubeformers and related equipment, such as fitting and clinching machines. ISM MAchinery is also a member of SPIDA, the Spiral Duct Manufacturers Association.

ISM Machinery offers spiral tubeformers such as the D-Max 1.2E and the Gore-Max Gorelocker. ISM also manufactures state of the art spiral fitting machines like the all-new Max-Stitch 16.i.