|

The Lockformer Vulcan Fiber Laser Cutting System is the next evolution in cutting systems. The Fiber Laser Cutting System was designed to meet the needs of sheet metal fabricators who were looking for faster, more precise cutting, better quality parts, and more features that would improve their productivity and profitability. Fiber laser cutting, as we know it today, revolutionized the sheet metal industry around the early 2010s as an alternative to plasma cutting for the light gauge sheet metal and HVAC duct and fittings fabrication industries. Here's how the Lockformer Vulcan Fiber Laser Cutting System optimizes the sheet metal cutting experience for fabricators and contractors. |

Key StatsMax Cutting Speed: 1,200 inch/min |

Getting to Know the Vulcan Fiber Laser Cutting System

The Lockformer Vulcan Fiber Laser Cutting System was designed with the needs of sheet metal fabricators in mind and is the optimal system for producing sheet metal HVAC fittings. While plasma cutting is another popular option for the sheet metal and HVAC industries that offers many benefits to fabricators, the Vulcan Fiber Laser Cutting System offers many advantages over plasma cutting the appeal to most fabricators.

The Fiber Laser has a cut speed up to 1,200 inches per minute (28 m/min) on 10ga to 26ga mild steel. This is up to 3X faster than a conventional plasma cutter. At the same time, the cut quality of the fiber laser is like that of a high definition plasma cutter on mild steel and stainless steel.

With minimal heat affected zone on the laser cut edge, the parts coming off the machine will cause less wear to downstream fabrication equipment. Minimal kerf combined with 4-axis controls enable the cutting of intricate patterns and unique edges.

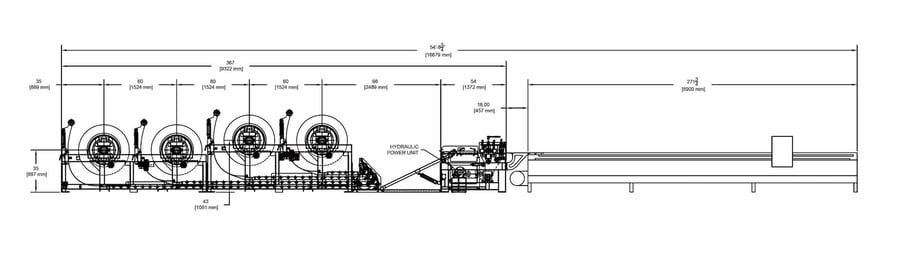

The standard Fiber Laser comes with a 5’ x 10’ zoned exhaust cutting table, but the machine is available with an option of a larger 5’ x 20’ table which produces minimal exhaust.

Coil Fed Vulcan Fiber Laser Cutting System

One of the most unique features of the Vulcan Fiber Laser Cutting System is the exclusive, patent-pending open architecture design (no enclosure) that provides access to parts directly from the table, eliminating the need for a pallet shuttle system. This design allows the operator to interact with cut parts while the machine is still cutting other parts. Most other laser systems are sheet extractors with closed architecture that burn whole sheets and eject the parts. The open architecture design also allows for the machine to be sheet fed OR coil fed.

Finally, equipped with a Windows 10® Professional PC with 19″ Monitor and Printer, the Fiber Laser can be integrated with most CAD to CAM software systems for maximum shop productivity and seamless connectivity with other machines throughout your operation.

See the Vulcan Fiber Laser at AHR Expo 2024The Lockformer Vulcan Fiber Laser Cutting System (5' x 20' table), along with 8 more of Mestek Machinery's top sheet metal fabricating machines, will be set up for live demonstrations throughout the 2024 AHR Expo on January 22 to 24, 2024 at the McCormick Center in Chicago, IL. Click here to learn more about visiting Mestek Machinery at the AHR Expo. |

|