Across the HVAC industry, corner insertion creates bottlenecks that impede productivity and block the process flow throughout your fabrication shop. For many contractors, corner insertion for fittings is a manual process which not only poses challenges to production speed, capacity, and flow, but it also takes up a significant amount of space on the floor. However, there is a machine solution that can help fabricators streamline the corner insertion process through automation, which in turn improves shop flow.

Automating Corner Insertion for Fittings

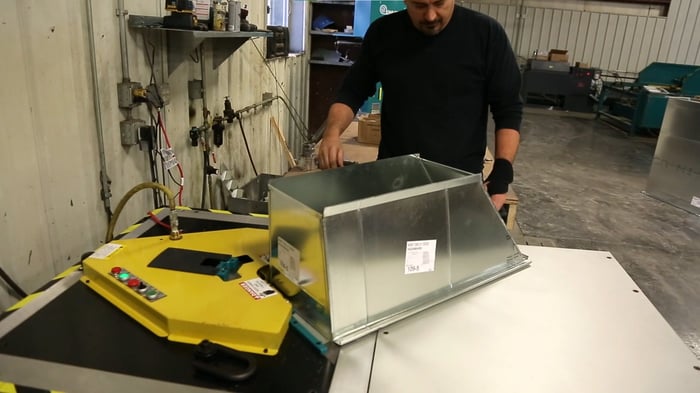

The Iowa Precision Cornermatic Plus and Cornermatic Plus Versa HVAC Ductwork Corner Inserter Machines are the ideal answers to automating transverse duct connector (TDC) and transverse duct flange (TDF) corner insertion into fittings.

For years, contractors have inquired on how to better the process of producing finished parts in the fittings area of the duct shop. Today's contractors seem to be standardizing on TDC and TDF for their commercial HVAC construction methods. However, the process of handling, inserting, and locking in these corners manually takes time and effort. A typical corner will be touched 8-10 times at a rate of eight corners per connection.

The Cornermatic Plus line is a completely hands-off approach to inserting TDC- and TDF-style corners.

The Iowa Precision Cornermatic Plus HVAC Ductwork Corner Inserter Machine automatically inserts TDC- and TDF-style corners and crimps them in less than 45 seconds per connection. The corners come in Strap Pak packaging at 80 corners per pack. The Cornermatic Plus can handle a gauge range from 16-26ga down to 2” throats.

The Cornermatic Plus is a freestanding, above-ground, table top machine, with features including:

- Full automation — no switches or foot pedals, simply push the fitting in and the Cornermatic Plus does the rest.

- The ability to complete 8 corner inserts in seconds.

- New quick-loading StrapPak™ packaging technology that speeds loading of the magazine directly from the shipping carton.

- Corners fed from below the work surface, allowing a clean and unobstructed work area.

The Cornermatic Plus Versa HVAC Ductwork Corner Inserter Machine provides all the benefits of the Cornermatic Plus, but with the added flexibility some contractors need to suit production. The Versa is installed with the capability of sitting on the workshop floor or in-ground and can be raised and lowered with a simple button press. Using the Versa in-ground is beneficial for projects involving large duct or heavy gauge fittings, while the above-ground position is ideal for fitting production.

The Right Machinery to Improve Shop Flow

When your shop thrives on productivity, you need the right solutions and equipment to keep your fittings fabrication process moving. Obstacles to a quick, efficient shop flow not only hinder your productivity and profitability but the quality of your finished product as well. Thankfully, if you're experiencing challenges with fabrication shop flow, you're not alone, and you can improve your productivity and flow with the right machinery, setup, and processes. Mestek Machinery is here to help you find the solutions and equipment for more efficient fittings production.

If you're ready to learn more about improving your shop flow with the Cornermatic Plus and other equipment from Mestek Machinery, check out the clip below and then register to watch our full shop flow video.