Prefabrication is on the rise in the HVAC/ductwork industry for a variety of reasons. Not only does prefabrication lower labor costs and increase safety by taking the duct production process off the job site, but in fact, prefabricated ductwork generally has fewer defects as product that is assembled on the job site. In this post, we will discuss ductwork prefabrication and how it leads to increased product quality.

High Quality Prefabicated Ductwork

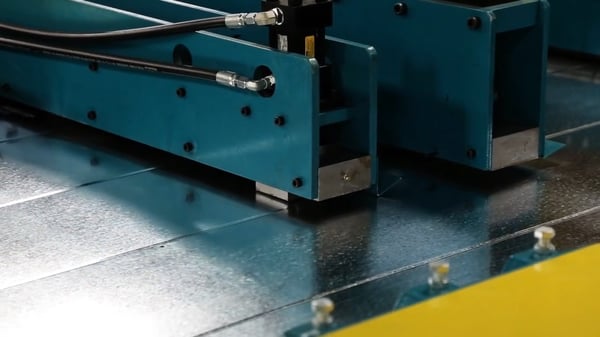

Prefabricated duct work for the construction industry delivers quality, consistent deliverables to the field. As all building and assembly work is carried out in a controlled environment, products are less likely to be damaged during final installation. Product can also remain clean and free of dirt and debris because pieces are not sitting on the job site waiting to be installed. Any defects in the product can be identified and corrected before the product is delivered to the job site, giving contractors peace of mind that the ductwork is in optimal condition and saving time that might have been wasted correcting any issues discovered during installation. Because it is easier for contractors to handle materials indoors as well as maintain production equipment, prefabricated ductwork is generally of a higher quality than duct work that is not prefabricated.