In our increasingly digital age, one of the best ways to improve the productivity of your metal fabrication processes is leveraging BIM data collected by your machinery. Using this rich data that lives inside the BIM model, you are able to automate the fab process, facilitate the flow of information through the process, and identify quality concerns. While this can be done manually, using the data available to you through BIM is not only more efficient but also gives you the ability to feed your fabrication process from design to fab.

Compiling Fabrication Data Using BIM

Using the information available in your BIM software, you have the ability to dictate where each of these pieces of product should go in the shop, as well as track critical benchmarks such as productivity, timing, and output by exporting this data. The content of your model becomes your fabrication work order. While this can be done manually on paper, what many contractors fail to realize is all the value of that benchmarking that's lost when you're working on paper.

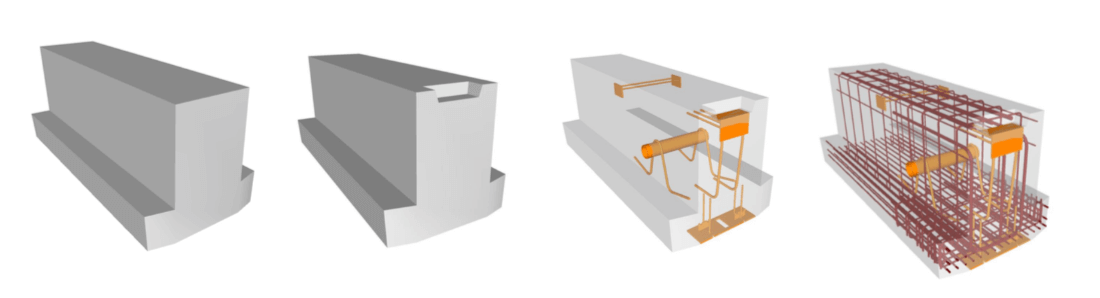

Working in BIM software allows you to capture all of the metadata that lives inside of your PDF and use it in different capacities through the fabrication process. As you begin to upload your drawings digitally, you can bring the 2D and the 3D together and compile all of that fabrication data that can be used to improve your processes, optimize your shop flow, and boost productivity as well as product quality.

At the same time, you will also feed this process with more sources of design data, including gauge, thickness, material type, duct type, and more. The more data you are able to feed into the system, the more you are able to eliminate confusion, ensuring the team has access to the correct file. Within BIM, you're able to see each work package and each segmentation to understand what work has been done as well as what roadblocks the project may have run into - lending more visibility into your process than paper and pencil design ever could.

Improving Collaboration and Visibility with BIM

Another advantage of BIM software is the ability to assess the productivity and output of your shop at any point in the process. You can leverage passive tracking for real time earned value as well as project analytics that have value to you, your partners and contractors, and your clients. This information is accessible to the shop, the field, and the VDC teams. Information permissions can be set so that administrators can see only the information they need to get their job done, but full visibility can be available to everyone on your team who needs access to the data.

By using BIM, we are enabling a paperless shop floor and we're moving towards more transparency, both in the shop and between the trades. We're moving toward version control, 2D and 3D viewers, and merging that information together. You're also able to automatically generate documents like the welder continuity log, weld tracking labels, etc. While paper may still have its place in our shops where appropriate, being able share this visibility, automate some of our processes for improved efficiency, and troubleshoot problems more effectively is what BIM allows us to do. When you have more control over your data and where it's flowing, you can use that autonomy to empower your business and improve it.